Look beyond Control & Monitoring…

Reliable and efficient operation of a hydropower plant greatly depends on the condition of its main equipment such as generators and turbines. With the best practice shifting towards condition based and predictive maintenance, the industry is undergoing a paradigm shift in the field of maintenance. And this has become possible due to the advancement in the technology for machine conditioning monitoring and data analytics.

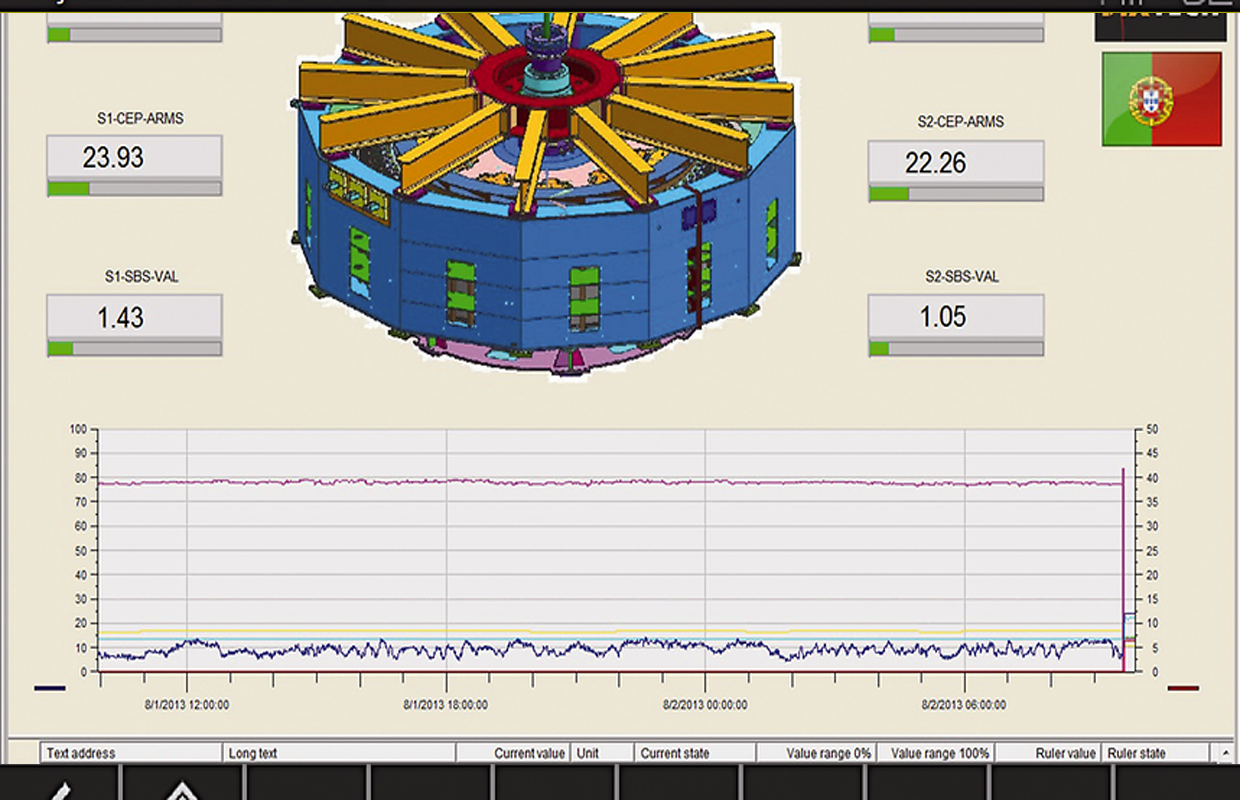

Online partial discharge and vibration monitoring systems are two of the crucial condition monitoring systems for a turbine-generator set. Other factors which can be monitored are generator airgap, rotor pole temperature, rotor magnetic field, ozone in the cooling air, cavitation in the turbine, etc. Advanced monitoring and diagnostic systems help evaluate the field measurement values and analyze the trends to provide useful operational information to the operation and maintenance personnel.

To fulfil the overall automation requirements, we can either integrate individual condition monitoring systems to the SCADA or supply complete monitoring and diagnosis systems based on the latest digital technology.